Service

Equipment supply

- MERSEN produces graphite parts for various applications (brake discs, industry, heat exchangers, wafer carriers, etc.).

- The resource at the Gennevilliers site is flared waste gas from the production furnace. It represents 300 kWth usable by a burner.

- Thermal CHP enables heating a machining workshop in winter.

- First H2P demonstrator installed at a client’s site

0 MWhe/an

Annual electricity production

0 MWh/an

Annual thermal recovery

0 tonnes/an

CO2 emissions avoided

| Client | MERSEN (Gennevilliers site) |

|---|---|

| Application | Graphite production |

| H2P Capacity | 15 kWe, 150 kWth |

| Cogeneration | Industrial building heating |

Service

Equipment supply

- ESSITY manufactures hygiene papers (toilet paper and hand towels) from recycled paper.

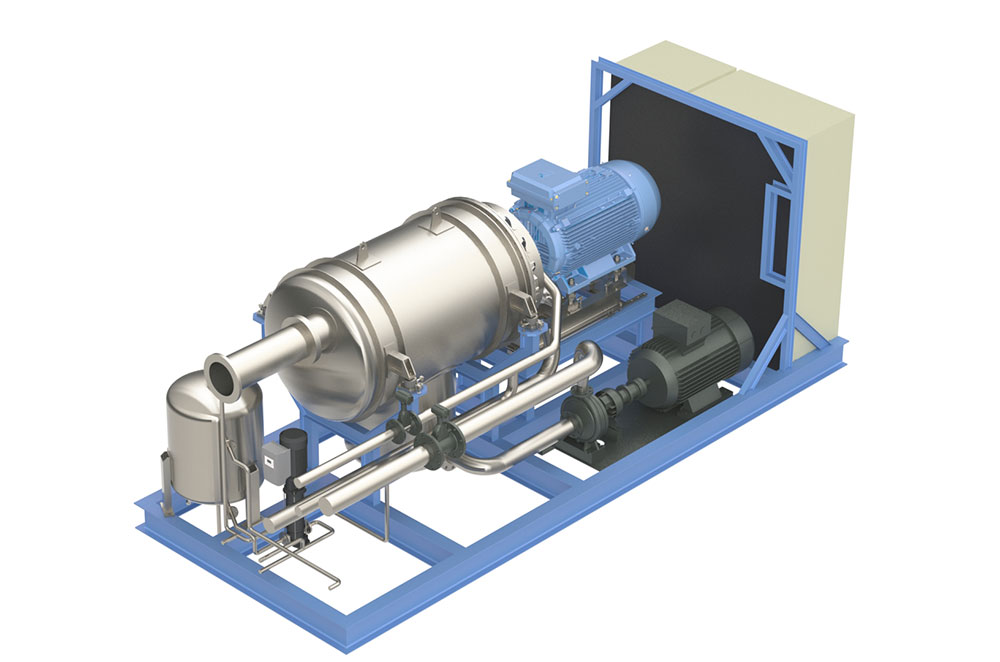

- A first demonstrator installation of the paper sludge recovery process, subsidized by ADEME, is currently being assembled and validated at the Hondouville site (small resource of 140 kWth at 900°C).

0 MWhe/an

Annual electricity production

0 MWh/an

Annual thermal recovery

| Client | ESSITY (Hondouville site) |

|---|---|

| Application | Recycled paper production |

| H2P Capacity | 20 kWe, 200 kWth |

| Cogeneration | Paper drying |

Service

Technical Expertise

- VICAT produces cement incorporating clinker, which is necessary for concrete performance. This clinker is produced in a rotary kiln from limestone and clay heated to high temperatures (1450°C).

- The thermal resource of the Montalieu furnace corresponds to 5 MWth at 300°C.

- Thermal CHP would be used to dry Solid Recovered Fuels (SRF), alternative fuels that substitute fossil fuels such as coal or natural gas.

Study conducted

To recover waste heat available from a cement kiln for drying solid recovered fuel.

Audit Duration: 2 months

| Client | VICAT (Montalieu site) |

|---|---|

| Application | Cement production |

| TS Capacity | 80-150 kWe, 1.5 MWth |

| Cogeneration | Drying of inputs |

Service

Technical Expertise

- FMI PROCESS produces sludge furnaces, generally from wastewater treatment plants.

- FMI PROCESS requested HEVATECH for a sludge incinerator project in Pavia (Italy).

- The targeted resource consists of 2 incinerators. It represents more than 3.1 MWth at high temperature (< 570°C).

- Thermal CHP will enable the drying of incoming sludge without additional energy consumption.

Study conducted

To recover waste heat available from an agricultural sludge incineration furnace for drying inputs.

| Client | FMI PROCESS, (Pavia, Italy) |

|---|---|

| Application | Sludge incineration |

| TS Capacity | 2 modules – 70 kWe / unit, 1,600 kWth |

| Cogeneration | Sludge drying |

Service

Innovative Project

- Project responding to the I-NOV 5 call for projects proposed by ADEME as part of France 2030.

- Increased turbine performance, efficiency, and maximum power, and optimization of its role in separating oil from water vapor.

Project Description

- Development of complex numerical models to simulate the behavior of high-velocity two-phase flows (liquid/gas) projected onto an impulse turbine.

- Parametric optimization of the turbine

- Development of a specific test device

- Development of a custom system for liquid/gas phase separation.

| Co-funder | ADEME |

|---|---|

| Duration | 24 months |

Service

Innovative Project

- Project funded by the AID-DGA RAPID scheme, in partnership with the French hot air storage specialist ECO-TECH CERAM.

- Development of an operational demonstrator for a thermodynamic solar power plant, capable of producing electricity day and night, utilizing an HEVATECH H2P hot air engine and ECO-TECH CERAM thermal storage.

Project Description

- Validation of the feasibility of a demonstrator combining engine, thermal storage, and electrical conversion.

- Design of a sizing tool for the integration of thermal storage into Hevatech systems.

- Continuous operation of the H2P engine under intermittent thermal source constraints.

| Funding | RAPID Scheme |

|---|---|

| Partnership | ECO-TECH CERAM |

Service

Innovative Project

- Project responding to the I-BAC SME call for projects proposed by ADEME as part of France 2030.

- Expansion of the TURBOSOL range for the recovery of lower temperature waste heat (range 200°C < T < 300°).

- Improvement of the electrical conversion efficiency of the TURBOSOL process for the current temperature range without CHP (300 < T < 600°C)

Project Description

- Studies on the vacuum implementation of the TURBOSOL process.

- Development and optimization of injectors and the turbine specifically for vacuum operation.

- Design and production of a TURBOSOL module with an electrical power output greater than 50 kWe, capable of recovering waste heat resources from 200°C.

| Co-funder | ADEME |

|---|---|

| Duration | 24 months |