HEVATECH and Advanced Cyclone Systems (ACS) partner to accelerate industrial decarbonization

We are proud to announce our strategic partnership with Advanced Cyclone Systems (ACS) to offer integrated waste heat recovery and high-performance filtration solutions for industrial applications. This collaboration builds upon a successful initial project we completed together for Essity and aims to significantly improve industrial energy efficiency while reducing emissions. In this partnership, we serve as the primary integrator of waste heat recovery systems, while ACS provides its advanced cyclonic separation technologies for high-temperature, particle-laden gas streams. Together, we address complex, scalable, and replicable industrial projects, particularly in energy-intensive sectors. Industrial Companies, EPCs, and Consulting Firms: Let's discuss your decarbonization [...]

HEVATECH Launches MAEVA: the First Dedicated Solution for Characterizing Industrial Waste Heat

MAEVA - Measurement, Audit, and Study of Energy Recovery - is an innovative solution dedicated to the characterization of industrial waste heat. This often-overlooked waste heat offers significant potential to improve competitiveness and reduce carbon emissions. MAEVA enables precise characterization of this heat by analyzing existing data and conducting on-site measurements. This solution relies on low-intrusive measurement tools, remote monitoring, and in-depth financial analysis. MAEVA enables industrial companies to maximize the energy recovery of waste heat to optimize their energy consumption. A comprehensive 5-step study: Analysis of existing data and acquisition of new measurements; Statistical processing and precise quantification of [...]

HEVATECH: at the Heart of Innovation for a more Sustainable Industrial Process!

HEVATECH warmly congratulates Essity on its new advancement towards zero industrial waste at its Hondouville (27) site. This significant initiative is supported by ADEME and NextGenerationEU, and we are proud to contribute to this innovative project by providing our expertise in energy recovery and industrial efficiency. Thanks to H2P technology, an innovative demonstrator has been implemented to transform recycled paper production residues into several valuable resources: A mineral valuable to the cement industry; An energy source for the site; Electricity and hot air, necessary for paper drying; This advancement represents a major step towards a more circular and less carbon-intensive [...]

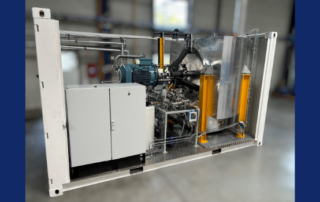

Qualification of our TURBOSOL: Optimized Waste Heat Recovery Solution

We are currently qualifying our TURBOSOL solution across a power range from 30 kWe to 80 kWe. This solution enables the recovery and utilization of waste heat, thereby contributing to a significant reduction in carbon emissions. Follow our news to discover how our innovation can transform the industry towards a more sustainable future.

Delivery of the innovative HEVATECH energy recovery system to the ESSITY client

Our client ESSITY received the high-temperature filter at its Hondouville site on July 19th, marking the first phase of the "CalBouVal" project. The next step is the installation of the H2P technology engine, enabling the recovery of waste heat in the form of compressed air and high-temperature hot air production. This project, co-financed by the State as part of France 2030 and operated by ADEME, aims to optimize a calcination process for paper sludge resulting from recycled wadding paper production by integrating our waste heat recovery system, converted into hot air and/or electricity. HEVATECH technology will enable ESSITY to achieve [...]

HEVATECH Finalizes the First Testing Phase of the SUN2P Project

The SUN2P project combines the coupling of the H2P product line's hot air engine with a thermal storage device from EcoTech Ceram to simulate continuous electricity production from concentrated solar heat. This first testing phase allowed for the simulation of solar heat production and the analysis of the kinetics of storage/electricity production cycles. The SUN2P project is part of the RAPID scheme (Support Regime for Dual Innovation implemented by the Defense Innovation Agency (AID)).

HEVATECH Validates a Second Milestone as Part of the MERSEN Client Order.

Our client MERSEN technically validated the system on April 26. This system aims to recover flare gases for local heating and electricity generation by combining a burner/exchanger and an H2P engine. Next step: delivery to MERSEN at its Gennevilliers site!

HEVATECH Expands its Portfolio of Industrial Decarbonization Solutions by Integrating H2P Technology.

HEVATECH completes its range of high-temperature solutions by acquiring H2P SYSTEMS, thanks to the support of EREN Group, and consequently, by adding the H2P and TURBOSOL product lines, covers a flue gas temperature range of 300-1000°C, thereby expanding its industrial waste heat recovery offering. Press release HEVATECH / H2P (PDF link)

The TURBOSOL Process Has been Awarded the ‘Solar Impulse’ Label!

To address ecological challenges, Bertrand Piccard and the Solar Impulse Foundation have identified tomorrow's clean and profitable solutions, including our TURBOSOL solution. The "Solar Impulse Efficient Solution Label" is designed to highlight existing solutions that are both clean and profitable and have a positive impact on the quality of life. To learn more about the labeled solutions: https://solarimpulse.com/foundation

HEVATECH Acquires New Technological Capabilities

HEVATECH acquires a workstation equipped with the CFD (computational fluid dynamics) simulation tool "Ansys Fluent". Previously entirely outsourced, fluid behavior modeling studies can now be conducted in-house!