Heat to power engines

Modules optimized for high-temperature recovery

A flexible and modular high-temperature CHP solution that is easily installed on industrial sites.

It uses only air as a working fluid and operates at low pressure, making it safe and easy to operate.

Based on recovery from hot flue gases (>600°C), the H2P system is designed to adapt to a wide range of energy needs. The H2P system is modular, with available power outputs from 2.5 kWe to 20 kWe by combining elementary building blocks (H2P engine + heat exchanger).

The H2P Module: An innovative engine for high-temperature recovery and hot air and electricity production

An original technology for waste heat recovery> 600°C

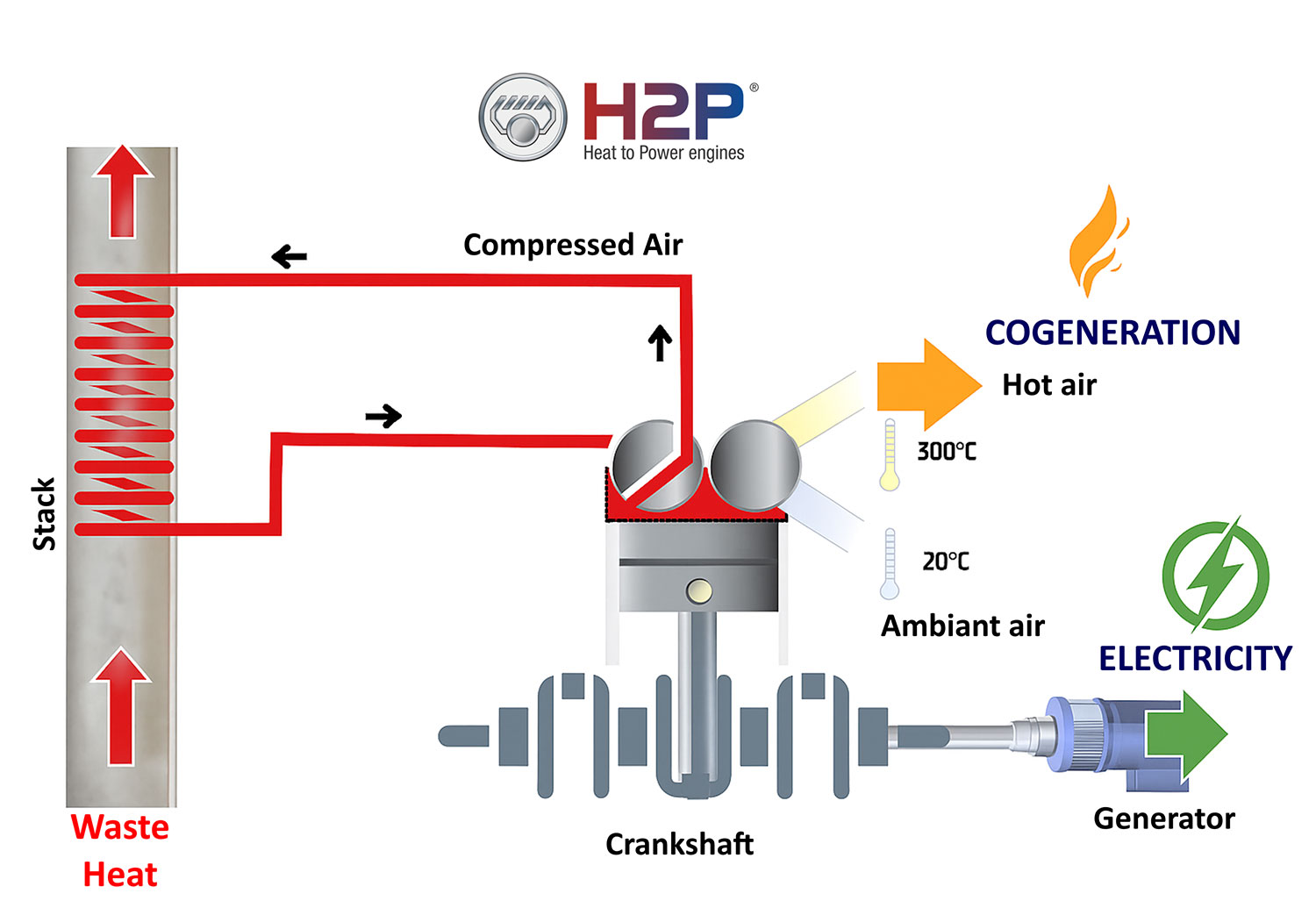

An original open-cycle hot air thermal engine

Operating without complex fluids, using only filtered air in each cycle, this external heat input engine combines:

• Low pressure for safe operation

• No ICPE constraints

• Simplicity of maintenance and installation

Production of electricity AND hot air > 300°C through CHP via a secondary heat exchanger

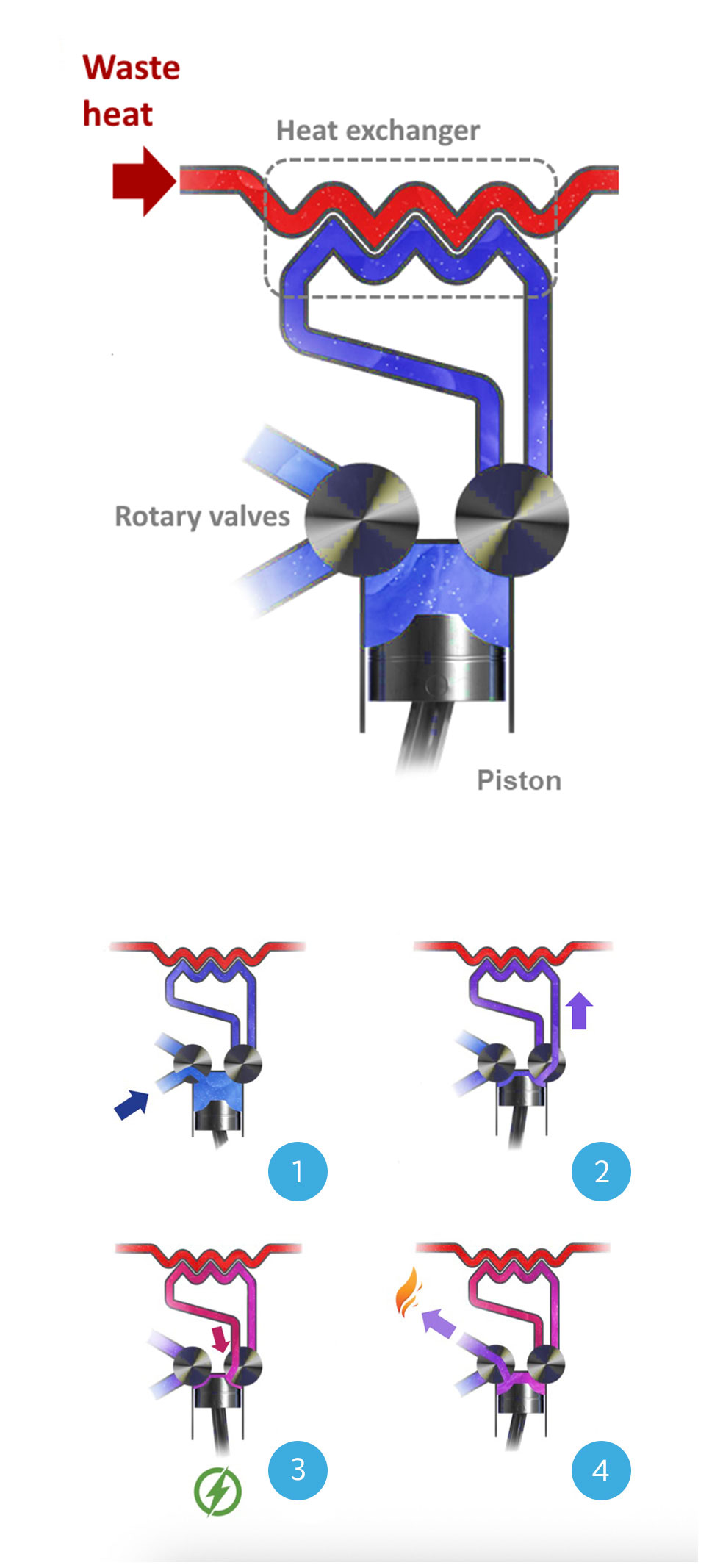

An innovative rotary valve system

The engine operates on a 4-stroke thermodynamic cycle, controlled by an original intake/exhaust system ensuring:

• Compression, heating, and expansion in a single cylinder

• Clean, high-temperature hot air available at the outlet for gas burner preheating, drying, and heating

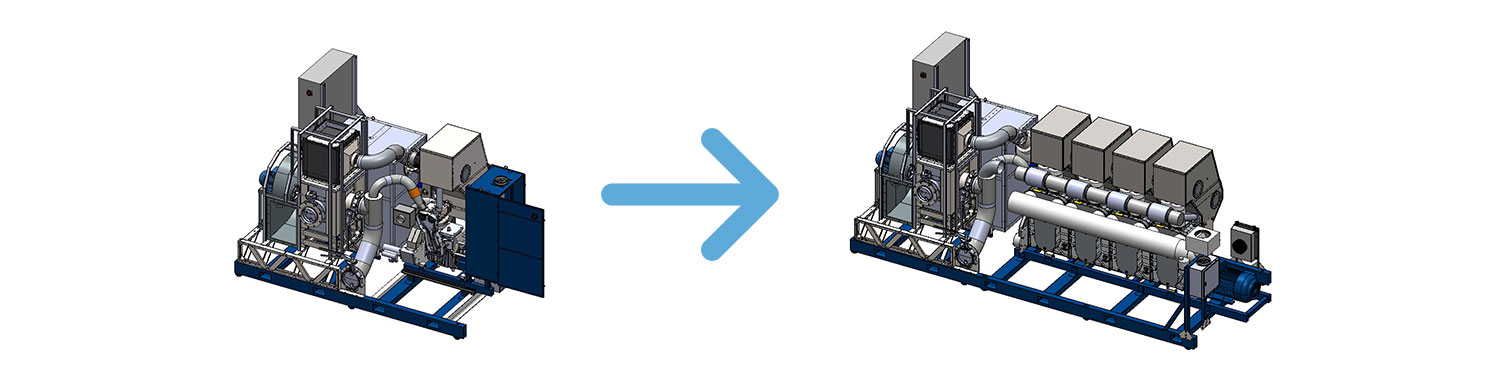

A modular and scalable architecture

• Standard 2.5 kWe modules, up to 20 kWe by coupling

• Compact design, ideal for integration into production lines or containers

Ability to produce hot air or compressed air through CHP according to industrial needs

The H2P Module: Description of the original cycle

- 1

Phase 1: Intake

The intake opens, the piston moves downwards.

Ambient air enters the working chamber - 2

Phase 2: Compression

The piston rises, compressing the air in the working chamber.

The heat exchanger inlet opens, allowing the entry of air compressed by the piston. - 3

Phase 3: Expansion

Once in the heat exchanger, the air previously compressed by the piston heats further and its pressure increases by drawing calories from the waste heat source.

The inlet towards the working chamber opens again, and the heated compressed air expands by pushing down the piston, thereby producing torque on the crankshaft. The mechanical coupling of the engine to an alternator enables electricity production. - 4

Phase 4: Exhaust

The piston rises, the exhaust opens, allowing the evacuation of clean hot air (<300°C).

This hot air can then be used directly or reheated with the remaining calories in the flue gases via a second heat exchanger.

CHP application cases

PRIMARY RECOVERY

COGENERATION