Recovering Waste Heat, Unlocking Industry’s Energy Potential

In a context of energy cost pressure and increasing pressure to decarbonize, industrial waste heat represents a valuable energy source that is still too often wasted.

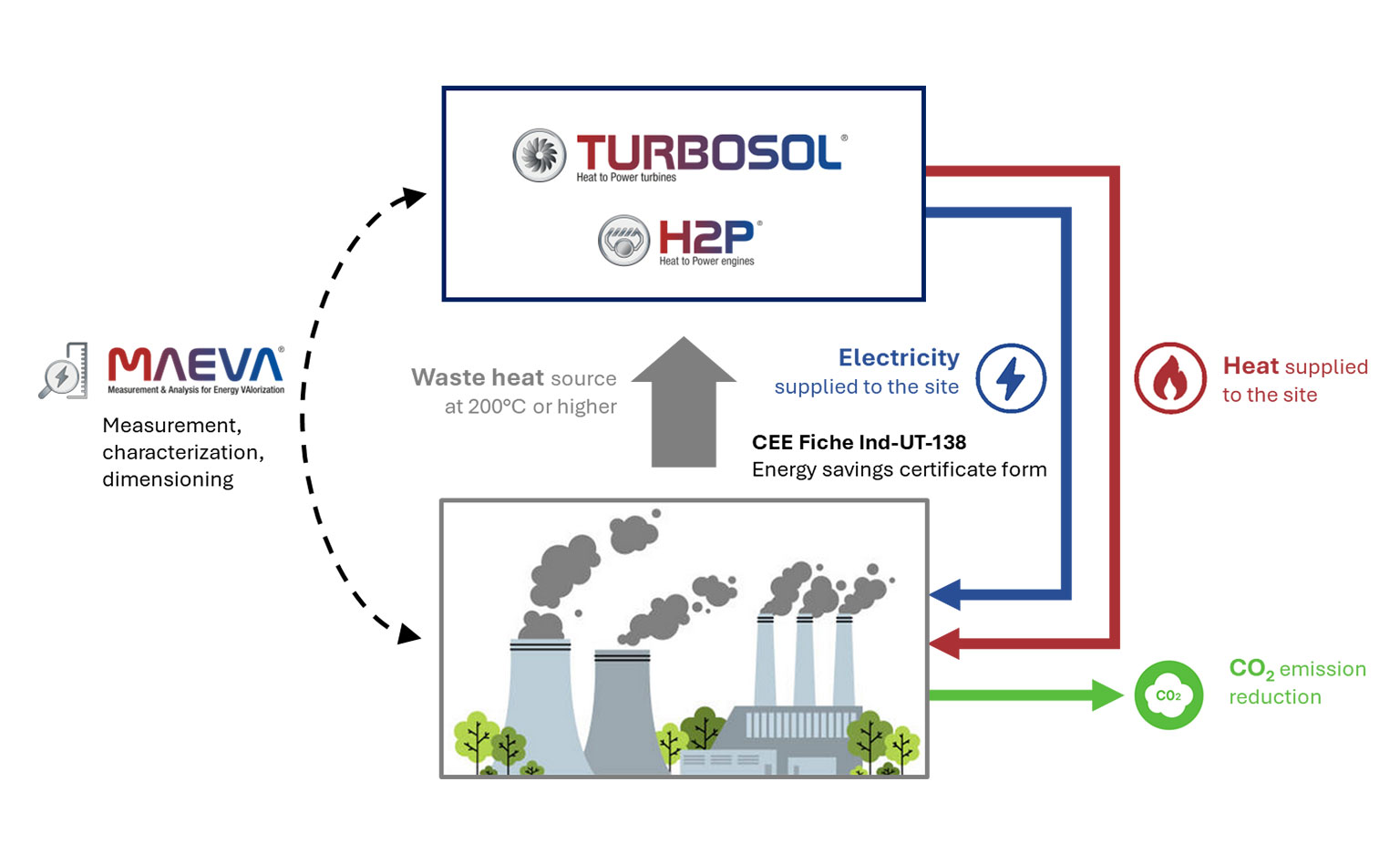

At HEVATECH, we design and install innovative solutions to transform this waste heat into electricity, useful heat, cooling, or other utilities, directly serving your processes.

A Concrete Response to Industrial Challenges

Up to 60% of the energy consumed in industry is rejected as heat. This energy source is an opportunity: recovering waste heat helps reduce energy bills, CO₂ emissions, and strengthen the energy autonomy of sites.

Our solutions integrate as close as possible to the processes, where thermal losses are maximal, to enable you to derive the greatest benefit from them.

Concrete Use Cases in the Field

Our solutions are designed to meet the specific needs of several industrial sectors, for whom recovering waste heat is an essential issue.

Production of electricity and useful heat from waste heat,

examples of CHP in the table below:

| IRON AND STEEL INDUSTRY STEELMAKING |

FLAT GLASS | LIGHT METALLURGY |

SPECIAL MATERIALS |

CEMENT PLANT | PAPER / CARDBOARD | INCINERATION | |

|---|---|---|---|---|---|---|---|

| Source | Thermal oxidizer Forge furnace 500-800°C |

Float cooling 200-500°C |

Aluminum foundry 500-1000°C |

Flare gas recovery 600-900°C |

Furnace vent recovery 300-400°C |

Paper sludge calcination 800-900°C |

Incineration of WWTP or agricultural sludge 500-700°C |

| Heat Sink | Building heating |

Building heating Biomethanizer supply |

Hot air burner supply | Building heating | RDF Drying Cooling CCUS | Paper drying LP Steam |

Feedstock drying |

Note: A heat sink refers to any form of outlet for heat that can still be recovered

downstream of HEVATECH processes (hot water or hot air)

These sectors are characterized by:

- significant unrecovered thermal discharges

- increasing pressure on emissions and energy costs

- high potential for integrating our technologies, with a rapid return on investment

Existing Systems

How do HEVATECH solutions integrate into factories?