Heat to power turbines

CHP solutions tailored to industrial needs

A fully integrated CHP solution capable of recovering waste heat streams from 200°C, installed turnkey indoors or in a container, and requiring low maintenance.

TURBOSOL operates at low pressure with non-aggressive fluids, ensuring reliability, safety, and ease of operation. Its optimized architecture limits critical components for enhanced robustness.

Modular, TURBOSOL covers power outputs ranging from 30 to 250 kWe, allowing for precise sizing of the target solution, reducing costs, and improving return on investment.

Unique technology that optimizes

energy recovery

- 1

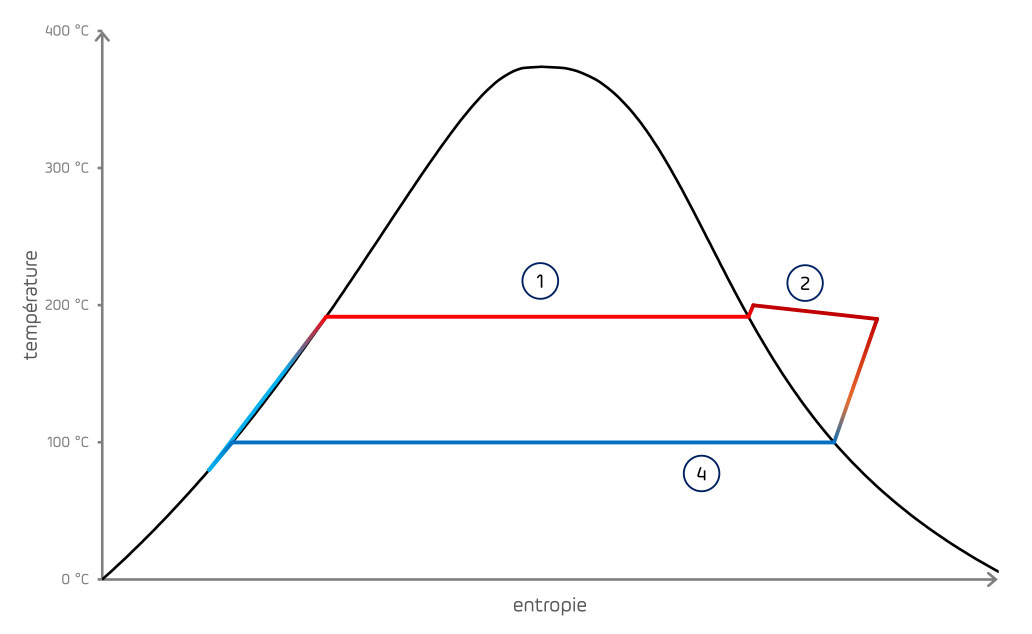

A unique thermodynamic cycle

Thermal energy is captured from industrial effluents by two fluid loops:

• thermal oil (dense heat transfer fluid)

• water (transformed into pressurized steam)→ Thermal energy capture

- 2

Dual-phase micro-injectors

The two fluids are mixed under pressure; the oil is sprayed as microdroplets and then accelerated by the steam expansion.→ Conversion of thermal energy into kinetic energy

- 3

A modular turbine

robust and standardized, allowing for simple power scaling by duplicating the dual-phase micro-injectors that feed it.

Coupling with an alternator ensures electricity production.→ Conversion of kinetic energy into electricity

- 4

CHP

The thermodynamic cycle closure requires steam condensation, thus allowing its thermal potential to be exploited.→ Production of usable heat up to 120°C depending on the application

TURBOSOL Thermodynamic Cycle

1- Steam Production

2- Mixture Expansion

4- Recoverable Heat Rejection

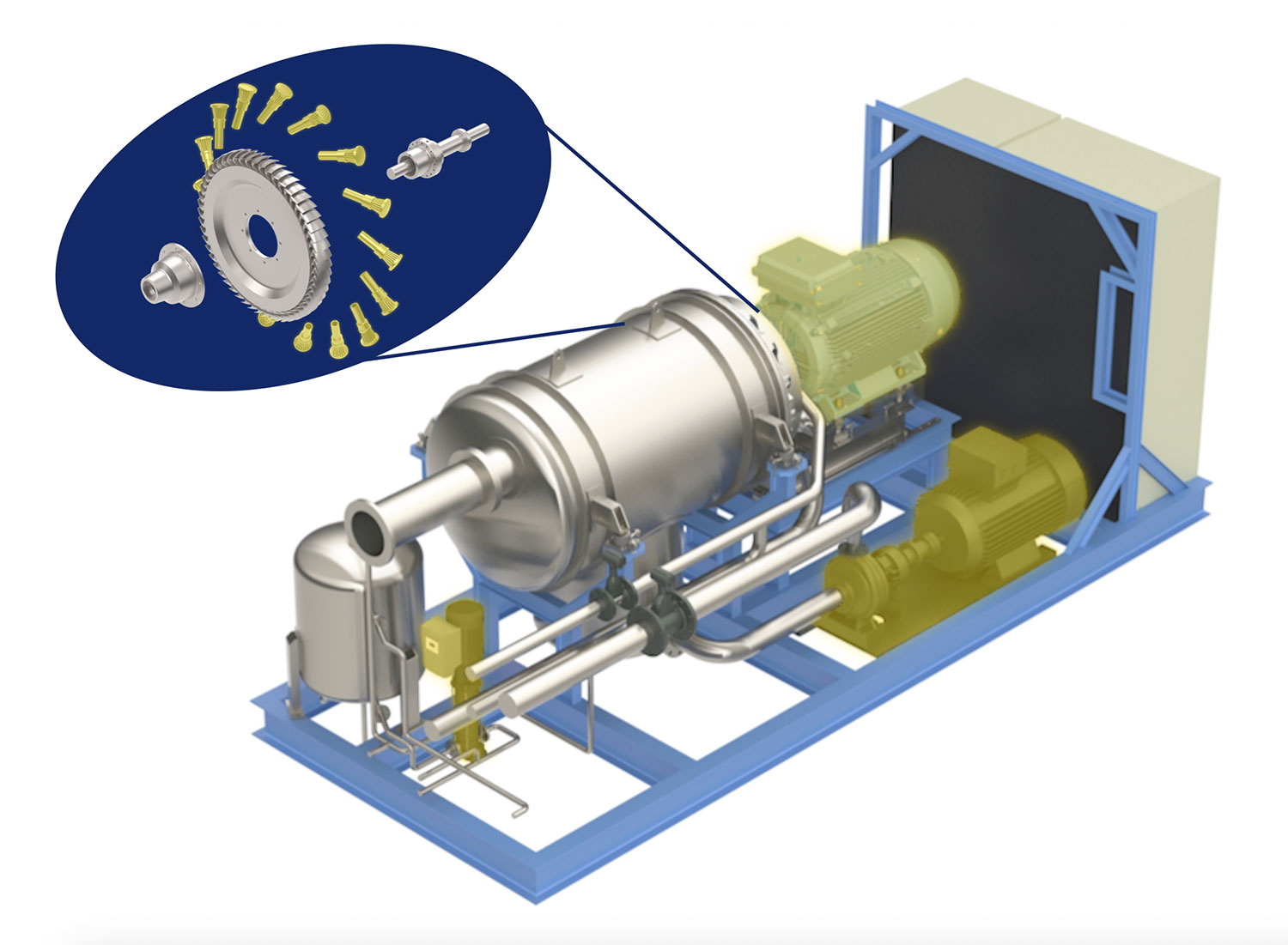

Modular design, robust system

and easy to maintain

A similar TURBOSOL technical base for the entire power range:

- Core of the process: turbine, duplicable injector type, associated mechanics

- Tank and steam and oil distribution capable of accommodating 2 to 16 injectors

- Chassis (general dimensions) and internal component layout

- Electrical cabinets

- Control system and program

A few modular components to select from a range to adapt to each use case:

- Number of injectors to install (from 2 to 16)

- Electric generator, oil pump, water pump (incremental models)

- Heat exchangers and condenser (client-specific)

In yellow: modular components

| TS-30 | TS-60 | TS-80 | TS-250 (coming soon) |

|

|---|---|---|---|---|

| Number of injectors | 2 | 4 | 5 | 16 |

| Net electrical output |

26 kWe 400V, 3ph, 50Hz |

58 kWe 400V, 3ph, 50Hz |

73 kWe 400V, 3ph, 50Hz |

245 kWe 400V, 3ph, 50Hz |

| Heat production |

380 kWth For water at 90°C |

755 kWth For water at 90°C |

945 kWth For water at 90°C |

3050 kWth For water at 90°C |

| TURBOSOL module dimensions |

6.0 x 2.4 x 2.6 m 2000 kg |

6.0 x 2.4 x 2.6 m 2500 kg |

6.0 x 2.4 x 2.6 m 3000 kg |

6.0 x 2.4 x 2.6 m 5000 kg |

TURBOSOL Range Specifications

CHP application cases

PRIMARY RECOVERY

COGENERATION

On-screen supervision, local network or remote