Valuation of waste heat sources, even in the most complex technical environments

In certain cases, waste heat is present in fumes referred to as “complex fumes.”

This is the case, for example, for fumes from waste incineration, or from the calcination of industrial sludge, from paper recycling, or from wastewater treatment plants.

To valorize the waste heat present in these so-called “complex fumes,” these fumes must be filtered, while preserving their thermal properties to avoid destroying the waste heat recovery potential.

Conventional bag filters, generally used before these fumes are discharged into the atmosphere, cannot withstand high temperatures, their limit typically being around 200 to 250°C.

It is for these reasons that HEVATECH has developed a novel filter, based on a conventional cyclonic filter, but featuring 2 unique characteristics:

- Maximum thermal loss of 20°C

- Tolerates fume temperatures up to 950°C

This makes it possible to access heat sources usually inaccessible due to high levels of dust, silica, or other particles, in order to recover this waste heat.

This filter was developed as part of a project co-financed by ADEME, and can now be adapted to a wide range of power outputs.

Valuation of waste gas sources, also known as flare gas

These process gases, generated by refineries in conventional and continuous ways or special material production processes, have significant energy potential, even though lower than that of natural gas or propane.

They are typically destroyed by open-air combustion in flares, to prevent their release into the atmosphere, primarily due to their high global warming potential, which is estimated to be 20 to 30 times greater than that of CO2.

HEVATECH has developed expertise in valuation of this so-called waste gas, by producing heat through a combustion chamber that meets the latest standards in combustion quality, and then by using the waste heat as an intermediate vector for energy transformation.

Thus, the heat produced from this waste gas is subsequently used to power HEVATECH machines, enabling the recovery of this generated waste heat in the form of electricity and CHP.

Example of flares at MERSEN: 3 x 250 kW

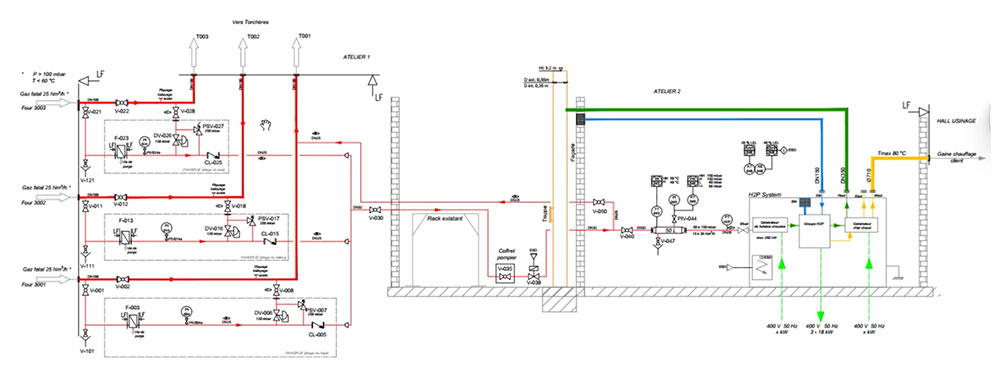

PID diagram for flare gas valorization at MERSEN

in the form of electricity and building heating